Fast forward! Time for the “Next Generation” from EFAFLEX

The highest quality solution for every application : EFAFLEX now offers all this with its “Next Generation” high-speed doors. The uniform concept offers many advantages.

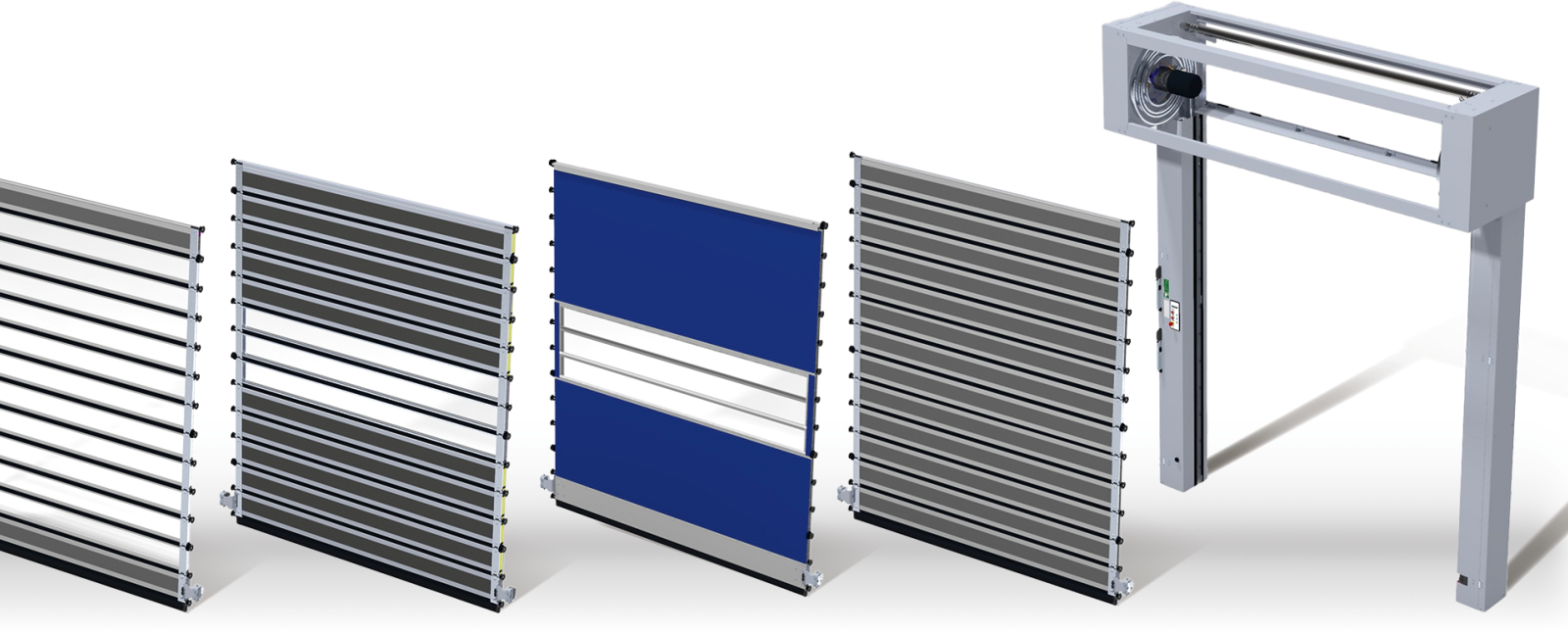

Just in time for their 50th anniversary, EFAFLEX presents an evolution of its spiral door: the “Next Generation” high-speed doors. The solution is a modular system with four door types, all based on the same concept. The result is a wealth of possibilities for customers.

Doors can be configured according to the modular principle

That means that each of the four different door types is available in three different variants – giving a total of twelve different door types. These are available with pre-configured equipment packages. In addition, special requests, such as a slanted end-shield, can be implemented quickly and directly at any time. The door activation control can also be integrated into the curtain box for extra space saving.

In the Premium version, each of the four door types comes with safety equipment including an EFA-TLG® door light grid, a manual emergency opening lever and spring breakage detection in both frames. In addition, the symmetrical door design features pivotable frame covers. This significantly simplifies maintenance and repair – especially in combination with EFA-SmartAssist®. EFA-SmartAssist® is a digital support tool with a remote diagnostic function via video link that provides immediate and expert support from EFAFLEX staff.

“Next Generation” high-speed doors increase sustainability

At the same time, the standardisation of the door design and the use of identical parts simplifies the production of all product components, whilst maintaining the usual EFAFLEX quality. Each type of door is designed for up to 400,000 load cycles per year, which makes them extremely long-lasting and durable. But the “Next Generation” high-speed doors are also next generation in terms of sustainability. The modular principle of the “Next Generation” high-speed doors conserves resources, which significantly reduces the door’s carbon footprint as early as at the production stage.

Energy consumption is also reduced as your buildings are used, with the amount of savings depending on the door configuration. EFAFLEX provides you with a “sustainability product passport” that includes all the necessary information about the sustainability of the door. This passport can be helpful for certifying your building.

The “Next Generation” high-speed door types at a glance

The EFA-SST® Therm minimises energy losses due to thermally separated EFA-THERM® insulation laths. As a result, the door also achieves a brilliant U value of 1.4 W/m²k and is thus our star in terms of sustainability. It is particularly suitable for closures in halls and buildings and is also suitable for noise protection applications due to the insulated laths.

The EFA-SST® Alux is very robust in its construction thanks to double-walled aluminium laths and can withstand up to 400,000 load cycles per year. In addition, the door system is certified according to DIN EN 12424 with Wind Class 5, i.e. it can remain in operation even under the highest wind loads and offers the option of certified Resistance Class 2 (WK2/RC2) when appropriately configured. This applies to all doors with the exception of the EFA-STR® Flex.

The EFA-STT® Clear high-speed turbo door offers an impressively fast opening speed of 3.2 m/s. In combination with the EFA-CLEAR® transparent laths, which ensure a clear view and open lines of sight, this door offers extra levels of safety in applications that involve high volumes of people. The EFA-STT® Clear is also aesthetically pleasing , as it allows daylight into the work area thanks to its transparent design.

The EFA-STR® Flex high-speed turbo roll-up door with opening speeds of up to 4.0 m/s enables efficient and fast logistics. The basis for this enormous speed is the door leaf, which is made of PVC-coated polyester fabric and reinforcements made of aluminium profiles, in combination with EFAFLEX spiral technology. The combination of flexible curtain and solid keder profiles is a very special feature on the door market. The great advantage of this model is that individual segments of the door leaf can be replaced separately.

Equipment packages for customisable doors

The range of doors is rounded off by four optional equipment packages to suit specific requirements. One such package is the ‘cold weather’ package, which is particularly suitable for an application range of -1 to -25 degrees. There is also a ‘process package’ that can be used in logistics and manufacturing areas.

In addition, the “Security 1” package with mechanical locking and the “Security 2” package with automatic locking are also available. Both packages can be integrated into an existing alarm system.

Next Generation in proven EFAFLEX quality

From its origins in Bruckberg near Munich, EFAFLEX has evolved into a global market leader in the field of industrial high-speed doors, with more than 1,400 employees and representatives on all continents.

The invention of the high-speed door spiral was an essential part of this development. To this day, it ensures that the door leaf can be wound up quietly, quickly and almost without wear. With this invention as a basis, numerous door variants have been created in the past decades to suit every need. The “Next Generation” high-speed doors once again deliver proven EFAFLEX quality. Thanks to their customisability, they can meet almost any requirement. It has never been easier to get robust, durable and sustainable doors that will also make your buildings “fast forward” and fit for the future.