How EFAFLEX’s Next Generation revolutionises the door market

Since time immemorial, EFAFLEX, the world market leader for industrial high-speed doors, has set the very highest standards for quality and durability. The “Next Generation” high-speed doors now offer a novel concept delivering many advantages.

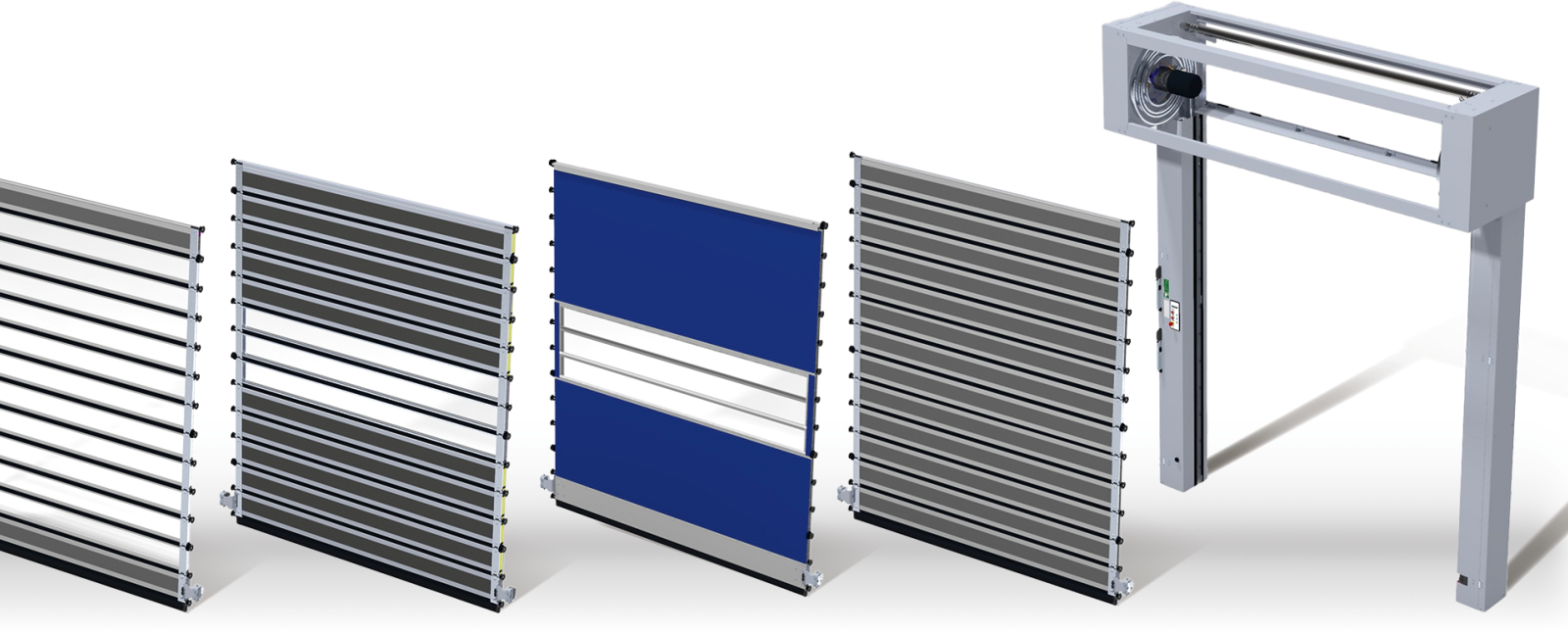

Just in time for their 50th anniversary, EFAFLEX is launching the next stage in the evolution of its spiral doors, to maintain its reputation as the solution provider for every requirement: the “Next Generation” high-speed doors, which offer a uniform basic concept that can be customised based on a modular principle.

Four door types are available in three levels, so that a total of twelve door variants are available. In addition, these variants can be configured with different equipment packages or individually designed. Special requests such as a slanted end-shield or the placement of the control in the curtain box can be implemented at any time.

Pivotable frame covers simplify maintenance and repair

The Premium versions of the “Next Generation” doors come standard with safety equipment including the EFA-TLG® door light grid, a manual emergency opening lever and spring breakage detection in both frames. In addition, the symmetrical door design features pivotable frame covers which significantly simplify maintenance and repair – especially in combination with EFA-SmartAssist®. EFA-SmartAssist® is a digital support tool that provides remote diagnostics by trained EFAFLEX employees using a video function.

At the same time, the quality of the product is also improved by the use of identical parts and the standardisation of the door construction for all four door types. The doors can withstand 400,000 load cycles per year, which makes the doors extremely sustainable. But this focus on sustainability starts as early as the production stage. Thanks to the uniform design of “Next Generation” high-speed doors, they leave the factory with an already significantly reduced carbon footprint.

Energy consumption is also reduced as your buildings are used, with the amount of savings depending on the door configuration. EFAFLEX provides you with a “sustainability product passport” that includes all the necessary information about the sustainability of the door. This passport can be helpful for certifying your building.

The “Next Generation” high-speed door types at a glance

Now we take a closer look at the four different door types and their special features:

- The EFA-SST® Therm offers outstanding insulation due to thermally separated EFA-THERM® insulation laths. This creates an enormous insulating effect that minimises thermal energy losses – perfect for closures in halls, buildings and also for noise protection applications.

- The EFA-SST® Alux is very robust in its construction thanks to double-walled aluminium laths and can withstand up to 400,000 load cycles per year. In addition, the door system is certified according to DIN EN 12424 with Wind Class 5, i.e. it can operate even under the highest wind loads and offers the option of certified Resistance Class 2 (WK2/RC2) when appropriately configured. This applies to all doors with the exception of the EFA-STR® Flex.

- The EFA-STT® Clear high-speed turbo door offers an impressive opening speed of up to 3.2 m/s. Together with the EFA-CLEAR® transparent laths, which ensure a clear view with open lines of sight, this door offers extra levels of safety in applications involving high volumes of people. The transparency of the door curtain provides a lot of daylight and thus offers potential savings on electricity. The door is also an absolute eye-catcher, by the way.

- The EFA-STR® Flex high-speed turbo roll-up door with opening speeds of up to 4.0 m/s enables efficient and fast logistics. The basis for this enormous speed is the door leaf, which is made of PVC-coated polyester fabric and reinforcements made of aluminium profiles, in combination with EFAFLEX spiral technology. The combination of flexible curtain and solid keder profiles is unique on the door market and also allows segments of the door leaf to be replaced individually.

In addition, EFAFLEX offers equipment packages for each door to meet individual requirements in special applications.

Packages for individual requirements

The ‘cold weather’ package is particularly suitable for use at -1 to -25 degrees, while the process package is used primarily in logistics and manufacturing. In addition, there are also the “Security 1” and “Security 2” packages, which are provided with a mechanical or automatic locking mechanism. The door lock is then connected to the alarm system in each case.

It has never been easier to get a door that can be individually adapted to every need and that combines robustness, durability and sustainability – not to mention the usual EFAFLEX quality. So, help your building “Fast Forward” – the anniversary motto of EFAFLEX – and make it fit for the future with a “Next Generation” high-speed door from EFAFLEX.

Based in Bruckberg in Bavaria, door manufacturer EFAFLEX has been present on the market for 50 years and has grown into the world market leader in the field of industrial high-speed doors, with over 1,400 employees and representatives on all continents. Nowadays, EFAFLEX offers custom, high-quality door solutions for every industry and every requirement.

An important component of EFAFLEX’s door systems is the spiral, which enables a quiet, fast and almost wear-free winding of the door leaf. This technology helps ensure that EFAFLEX doors are durable, robust and sustainable, as they achieve a much higher number of door cycles than comparable doors from other companies.